2.8kWh 3000W Electric Bike

Back in 2017, I began my journey of building eBikes for commuting. My first bike was a great start and had decent range and top speed, but after a year or so of riding it, I was yearning for more. Over the next couple years, I built several newer revisions, including one incredibly involved model that I built with my friend Cian using LiFePO4 prismatic cells left over from a failed hybrid electric bus project in Madison.

Unfortunately those cells severely underperformed compared to the datasheets and were incredibly heavy, despite all the work we put into it.

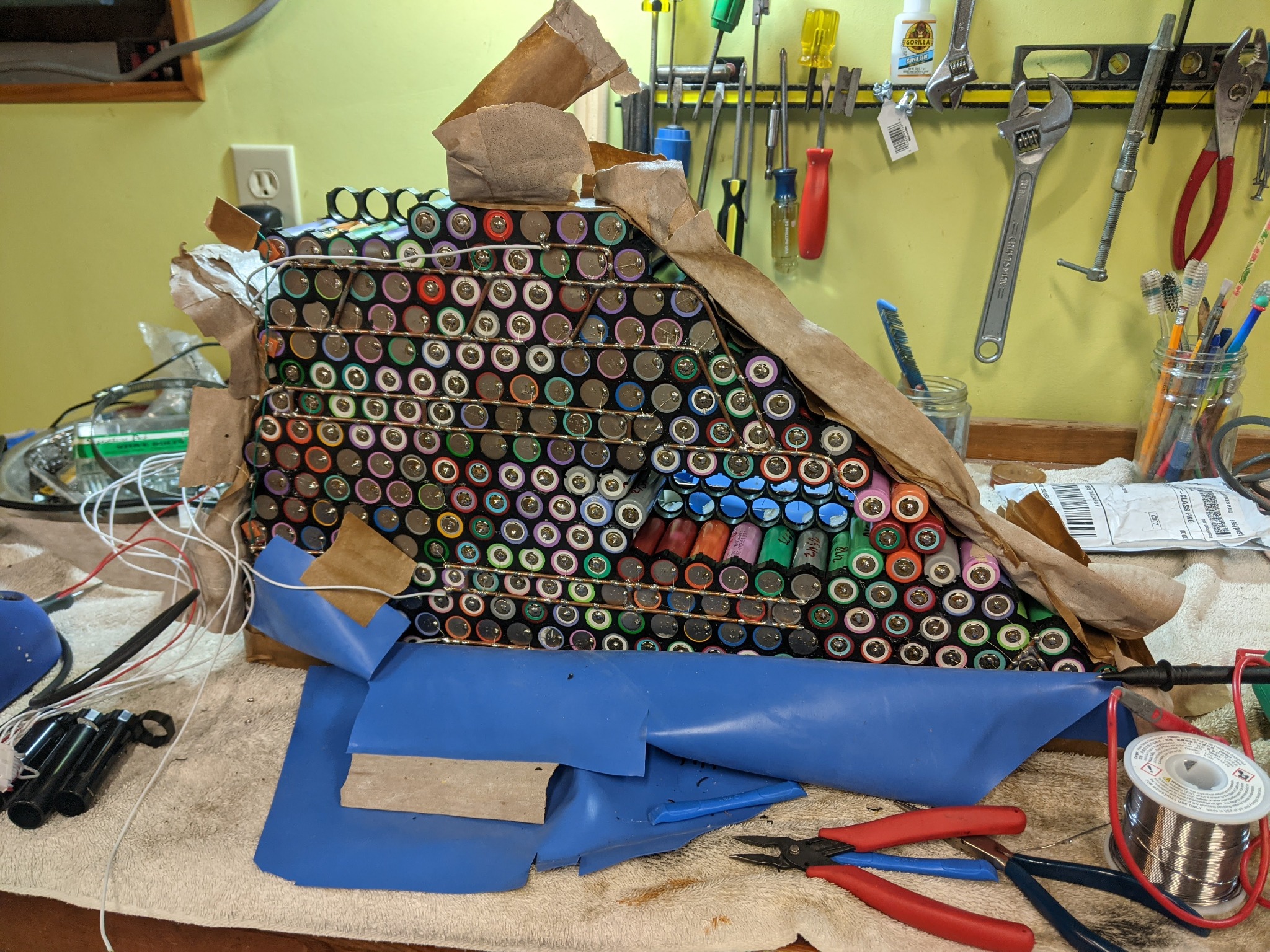

I decided it was finally time to switch to lithium ion despite it being difficult to find cells to use for a reasonable price, since I was tired of having a super heavy bike that could not go very far. 18650 cells are incredibly commonly used in laptop batteries, and the nice thing about getting used cells from laptop packs is that cells which go bad later into their life will take out a whole battery pack, but the rest of the good cells are left in a useable state. I reached out to a couple local computer stores in town and eventually found one that was willing to give me a massive box of over 100 laptop batteries from their recycling. With these in hand, I spent several months disassembling, checking, capacity testing, and watching the state of the cells to determine which ones were still useable. Meanwhile I had come up with a new idea for the battery enclosure, and cut out all the aluminum parts I needed to make it. I decided to make the pack out of these super convenient snap-together hexagonal 18650 holders.

After determining a suitable layout for 324 cells set up in a 18S 18P configuration that would fit within the bike's center frame, I used a tool called repackr to pair them based on their capacities to make equal capacity parallel sets. Then began the process of assembling them into the cell holders and wiring busbars.

Since all of the cells are used, I was wary about connecting them directly together with full gauge nickel strip or copper wire. At home, it is difficult to make per-cell fusing by hand without using soldering, since industry techniques use laser welding, ultrasonic welding, or microscopic spotwelds to attach ~30 gauge wire to each cell. I developed a technique which put the least amount of heat into each cell by first roughing the cell contact surface, then applying liquid flux, and finally very quickly "tinning" the cell with a blob of solder on a flat soldering iron tip, a process which took less than 2 seconds. When it was time to attach each fusing wire, I simply had to heat the wire and solder attached to the cell for a second and it would instantly bond.

The battery is also equipped with a "smart" BMS that connects over Bluetooth and has capacity, per parallel set voltage monitoring, and range estimates based on motor speed. Only once during the battery's life in 2022 did I notice a small issue with the pack becoming unbalanced, and quickly remedied it by replacing a faulty cell in parallel set 10. Since I finished building it in early 2021, I have put over 5000 miles on the bike, and I'm coming up on 6000 right now. I use it to commute to class every day that it is safe to do so, and drove it to work regularly. It's really nice to ride since if I need to I can keep up with traffic easily, but usually I ride it slower to get better range. On a 85% charge (to preserve cell life), I easily get 50 miles riding it even in city traffic. With a slower ride, I can get up to 80-100 miles depending on traffic and temperature.

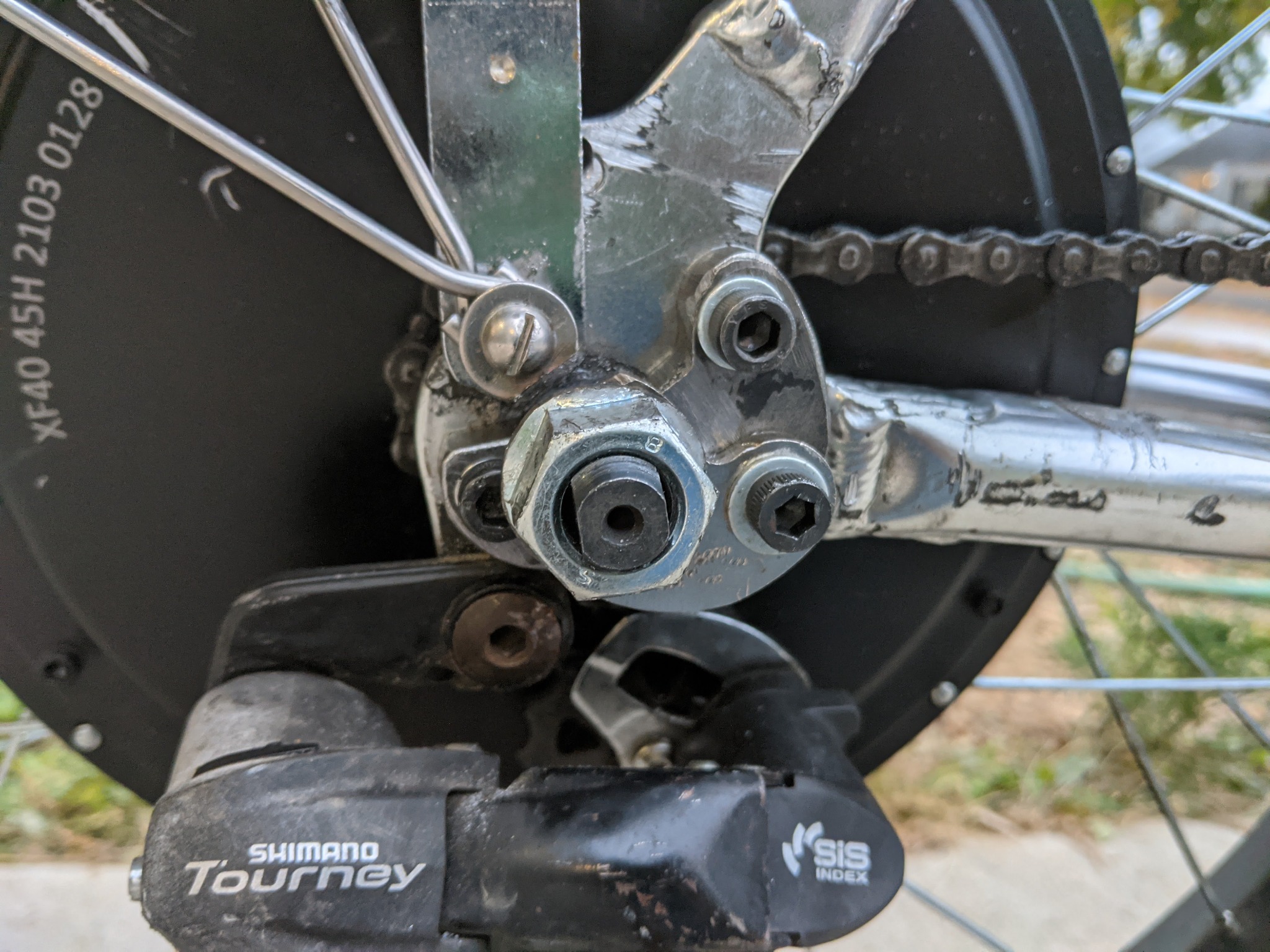

Since there are so many cells in parallel on the pack, the peak power of it ends up being close to 100A (5.5-6kW depending on charge), and it can comfortably handle 1-2kW constantly. Originally I had a 1500W motor on the bike from the LiFePO4 cell build, but after pulling a heavy load up a steep hill with it once, the motor was accidentally burned out in 2021. Since then I've replaced the motor with a MXUS 3KW turbo motor that can handle 6000kW peak and a Sabvoton 100A FOC sinewave driver, and it works insanely well for hauling all sorts of cargo (and also crazy fast and silent acceleration).

This bike and the past ones that led up to it were what really got me into the world of EVs, and I would highly encourage others to try building an eBike someday! It can be a super fun and fulfilling project that lasts you for years while being incredibly useful too.

Post a comment